How Long Should a Webbing Sling Be in Service For?

How Long Should a Webbing Sling Be in Service For?

Blog Article

When it comes to lifting and rigging operations, safety is the top priority. One of the most important tools used across industries is the webbing sling. But how long should a webbing sling be in service for? The answer depends on many factors, including usage, maintenance, and quality.

Understanding Webbing Slings

Webbing slings are made from high-strength synthetic materials like nylon or polyester.

They are lightweight, flexible, and strong enough to handle heavy loads.

These slings are commonly used in construction, logistics, manufacturing, and shipping.

At Juli Sling, we provide durable and reliable webbing slings that meet international standards.

Our webbing sling catalog includes a wide range of options to suit different lifting needs:

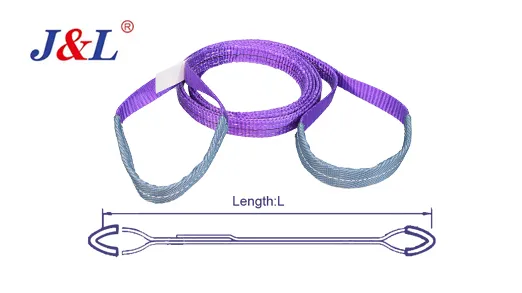

- Eye Type Webbing Slings

- Endless Webbing Slings

- Heavy Eye Webbing Slings

- Round Slings

Each type offers unique benefits and is built for specific applications.

Whether you need to lift pallets or delicate machinery, we have the right solution.

How Long Can You Use a Webbing Sling?

The service life of a webbing sling varies depending on several key factors:

- Usage Frequency

- Slings used daily may wear out faster than those used occasionally.

- Regular inspections help identify signs of damage early.

- Working Conditions

- Exposure to chemicals, UV rays, or extreme temperatures can reduce lifespan.

- Avoid using slings in harsh environments unless they are specially designed for it.

- Maintenance and Care

- Clean slings after use and store them in dry, cool places.

- Never overload a sling or twist it during operation.

- Quality of Materials

- High-quality slings last longer and perform better under stress.

At Juli Sling, we use only premium fibers to ensure long-lasting performance.

- High-quality slings last longer and perform better under stress.

Why Choose High-Quality Webbing Slings?

Using low-quality slings can lead to accidents, delays, and higher costs over time.

Investing in trusted products ensures safety, efficiency, and peace of mind.

Here’s why our customers choose Juli Sling:

- Superior Strength and Durability

Our slings resist abrasion, stretching, and wear even under heavy use. - Customization Options

We offer custom lengths, widths, and load capacities to match your exact needs. - Safety and Compliance

Every sling meets ISO and other international safety standards.

We test each product before delivery to ensure full compliance. - Versatility Across Industries

From construction to shipping, our slings work well in any environment.

Explore Our Webbing Sling Catalog Today

If you're looking for dependable lifting solutions, our webbing sling catalog has everything you need.

We offer competitive pricing, fast delivery, and expert support for every customer.

You can browse our full selection online or contact us directly for personalized recommendations.

Let us help you find the perfect webbing sling for your next project.

With Juli Sling, you get more than just a product — you get a partner you can trust.

Summary

In conclusion, the service life of a webbing sling depends on how it is used and maintained.

High-quality slings from trusted suppliers like Juli Sling last longer and perform better.

We are proud to be a leading supplier of industrial lifting equipment worldwide.

Visit our website today and explore our complete webbing sling catalog.

Let Juli Sling support your lifting needs with safe, reliable, and customized solutions. Report this page